INSCX exchange Europe Limited is a company incorporated in the United Kingdom trading as INSCX exchange Central Clearing Limited. INSCX stands for the Integrated Nano-Science & Commodity Exchange and is a commodity exchange system specific to trade in Nanoscience and Nanotechnology (N&N) and other commodities ranging from base oils, polymers to pigments. We are based in the UK, Ireland, India and also operate a representative facility in the United States. Founded as a concept in 2009, operating since 2011, we provide our customers with a number of tools and services across the time zones of Europe, Asia and the Americas.

These range from providing subscription access to a live electronic trade platform for physical delivery and price discovery in base oils, polymers and speciality materials, an online nanomaterials sales portal where over 5,000 variants of engineered nanomaterials are listed, materials certification and toxicology services for nanomaterials, a market system to trade industry-focused knowledge in Nanoscience and Nanotechnology, and bespoke consultancy geared to provide industry a roadmap to advance the compliant integration of nanotechnologies.

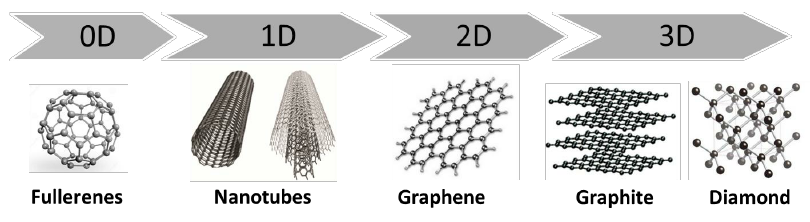

- Buy Nanomaterials Online – We provide a platform where research establishments, industry and end users can purchase nanomaterials online. Over 5,000 materials are available for immediate order, all supplied by verified, reputable producers who have been audited by ourselves to ensure the highest level of quality and reliability. We supply nanomaterials according to the thematic classes of Carbons, Ceramics, Compounds, Dispersions, Functionalised, Metals, Mixed Metal Alloys, Oxides, Photonics and Salts, Purchase Materials HERE

- Physical Trading – INSCX operates a live electronic dealing platform for high-volume commodities ranging from Polymers, Base Oils, Titanium Dioxide (matched bargain basis) and bulk nanomaterials on an electronic basis. Our trade services and platform access is available to registered producers, end users and trading members who supply/source INSCX listed categories of materials for physical delivery, each confident the Exchange system acts to underwrite the performance of buyer and seller. Read More

- Price Discovery – Both the nanomaterials research platform and the live dealing platform is available to registered subscribers who require accurate and real-time price discovery. Read More

- Materials Certification – Subscribers can access a comprehensive suite of the latest characterisation tools available to the Exchange to certify engineered nanomaterials, objects and devices. This service is a cost-effective benefit to producers and end-user seeking independent verification of materials. Read More

- High-Performance Nanomaterial Dispersions – Both nanoproducer members of INSCX and downstream users can access high-performance / high-volume / state-of- the-art fluid mixing facilities for toll processing dispersion of engineered nanomaterials. We can provide complete nanomaterial sourcing, formulation, dispersion and packaging solutions for members who require optimum nano-functionality in their materials. To enquire, simply complete the Contact Form

- Toxicology Assessment – Nanotechnology safety and risk assessments are cost effectively provided to support commercialisation of nanotechnology materials and products. Read More

- Compliance – INSCX has operated since launch a live real-time track/trace mechanism to record trade in engineered nanomaterials termed Downstream Audit Sequencing (DAS). This mechanism now available online to any nanoproducer is the only global trade reporting, traceability mechanism for engineered nanomaterials worldwide. DAS will be of benefit to insurers and regulation agencies concerned with risk identification and oversight as the system advances means to benchmark lifecycle analysis from source to destination of nanomaterials that are purchased or reported through the Exchange system. In addition, we provide bespoke consultancy services to assist organisations either engaged in the fabrication and supply of nanomaterials or wishing to integrate use of nanomaterials. Our aim is to assist further compliance with the evolving regulatory standard in this field of material science as stipulated by REACH and US TSCA legislation. Read More

- Knowledge Trading – INSCX provides a marketplace where the Knowledge Economy in nanoscience and innovation can be traded, bought or sold between the research community and industry with a greater emphasis on cost, objectivity and the deliverable. We offer this system so industry and the research community can interact more efficiently with one another. Are you for example, a business keen to develop new materials or products using nanotechnology, but wary of where to obtain objective research or costs involved? Are you a researcher in nanoscience with innovative research, but no customer? INSCX provides the methodology where these knowledge requirements can be put to auction, or a knowledge content offered for sale. While we retain a comprehensive database of focused research in nanosciences already, we also offer a researchers means to continually update this content. Read More

Please complete the form below if you would like to contact us. Alternatively, make contact by phone during Asian, European and/or US business hours.

By Phone:

EU: 353 71 985 3714 / UK: 44 (0) 203 137 5187 / 44 (1782) 454 144 / USA: 1 646 470 4911 / India: 91 9779 55077